Understanding the differences between a heat pipe heat sink and a traditional air-cooled structure is essential for teams working in mechanical components, thermal modules, and heat-dissipation engineering. These solutions appear widely in industries served by Dingmetal, where project specifications often require predictable temperature control, stable performance, and precise mechanical integration. A heat pipe heatsink combines several elements—a metal base, heat pipes, and extended fin arrays—to move heat efficiently through phase-change mechanisms. In contrast, traditional air-cooled heat sinks depend solely on conduction across solid metal and convection provided by surrounding airflow. Comparing these two approaches helps procurement teams and R&D engineers evaluate suitability for various thermal loads and design constraints.

Thermal Behavior, Heat Transfer Mechanisms, and System Responsiveness

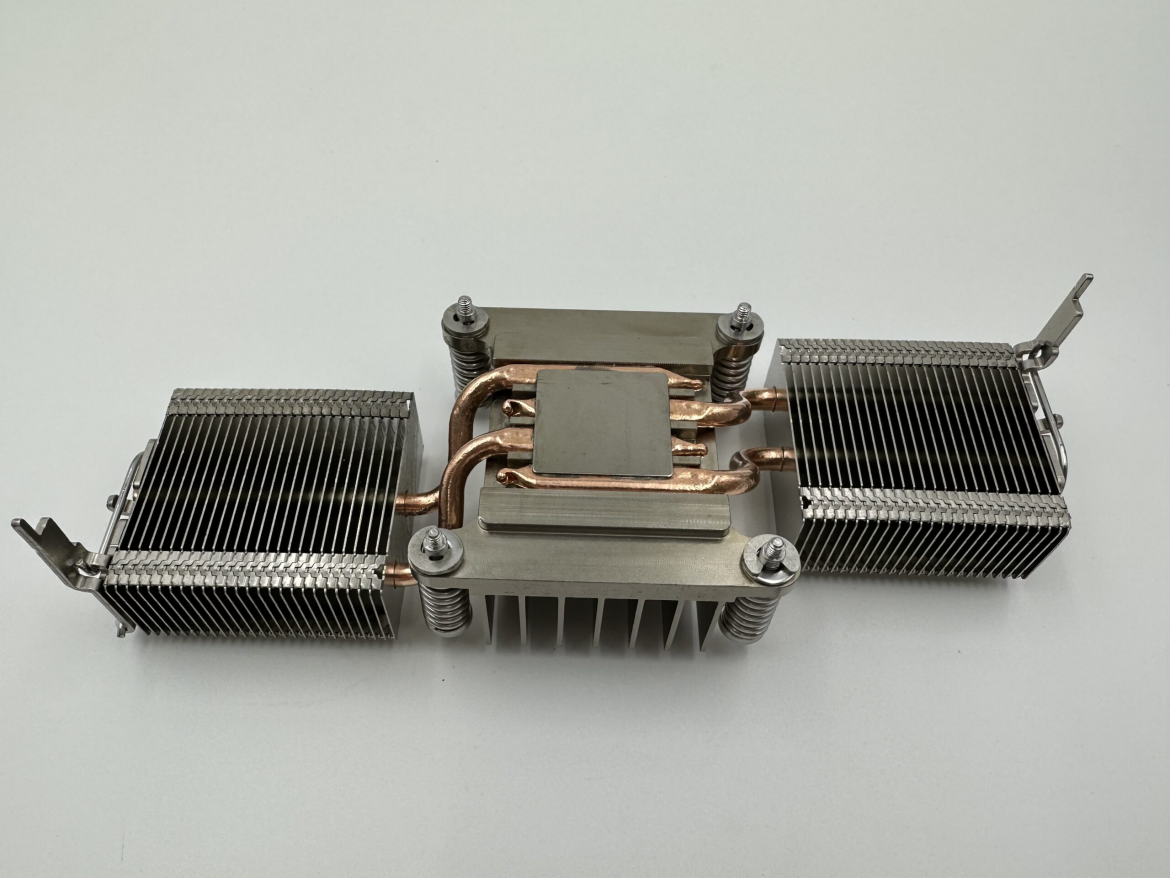

When examining thermal performance, a heat pipe heat sink stands out for its ability to move heat quickly away from the source. Internal heat pipes use evaporation at the heated zone, followed by vapor movement toward a cooler region where condensation occurs. Through capillary action, the fluid returns and repeats the cycle, helping a heat pipe heatsink distribute heat across a larger fin area with minimal delay. This reduces temperature spikes and improves stability under fluctuating power levels.

Traditional air-cooled heat sinks still serve many applications effectively, especially when heat loads remain moderate and airflow is not restricted. Their simpler metal-based conduction allows reliable operation in uncomplicated environments. For industries connected with Dingmetal, thermal density is often higher, and design spaces are limited, making uniform heat spreading a priority. Under these conditions, heat pipe-based designs can sustain better thermal equilibrium without drastic structural changes. Including the natural expansion of fin area improves heat dissipation while maintaining manageable weight and size.

Cost Considerations, Mechanical Reliability, and Integration Factors

Cost remains a central factor when comparing the two technologies. Traditional air-cooled heat sinks typically require extrusion, stamping, or machining, making them straightforward for cost-sensitive projects. A heat pipe heat sink contains additional manufacturing steps—pipe filling, sealing, and assembly—but its long-term thermal benefits often offset the initial expense. For example, a heat pipe heatsink reduces localized heating on surrounding components, helping extend service life and decrease the need for redesigns caused by thermal stress.

Reliability also plays a key role in selection. The sealed-loop structure of heat pipes provides consistent performance during long operating cycles. Many industries value predictable quality, dependable delivery timelines, and responsive technical support, areas where companies like Dingmetal provide advantages through stable production processes and service coordination. In compact assemblies or precise mechanical frameworks, the reduced size-to-performance ratio of heat pipe solutions helps maintain structural efficiency without compromising airflow paths or mounting methods.

Conclusion: Choosing the Appropriate Cooling Structure for Each Application

Selecting between conventional air-cooled solutions and a heat pipe heat sink ultimately depends on system requirements, spatial limits, and thermal expectations. A heat pipe heatsink offers higher thermal responsiveness and more uniform heat spreading, making it well suited for dense modules or environments where stability is essential. Traditional air-cooled heat sinks remain practical for simple, low-power equipment where budget and structural simplicity are priorities. By understanding how each method operates—phase-change-based transfer versus solid conduction—teams can align cooling strategies with performance goals. As more industries adopt compact and high-efficiency designs, clear evaluation of these differences supports consistent performance and dependable product integration.