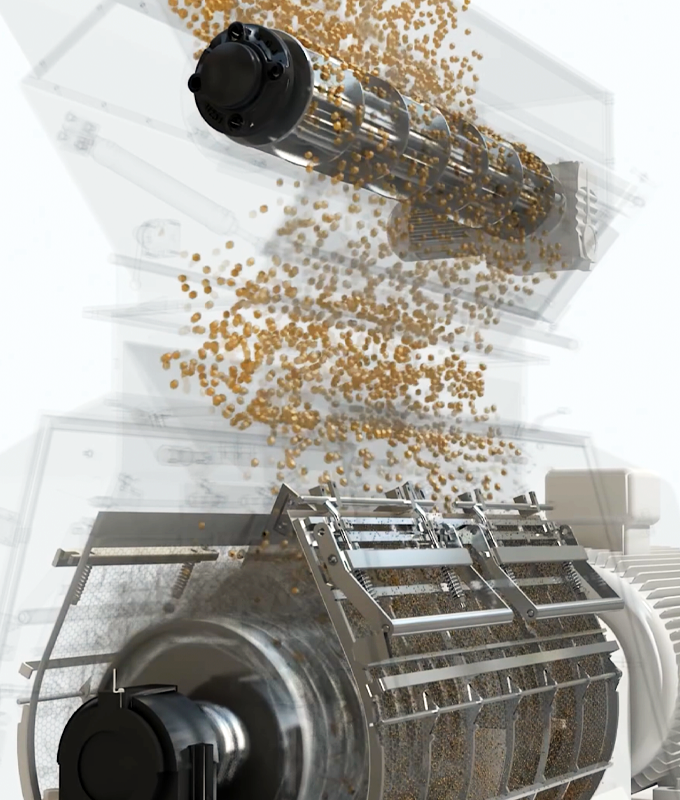

Effective feed processing relies on powerful and efficient raw material size reduction. FAMSUN, a prominent manufacturer of feed and food engineering machinery, delivers robust solutions like the SWFP66 Series Hammer Mill – a versatile hammer grinder machine designed for superior performance. This equipment forms a critical foundation for consistent, high-quality feed across diverse animal nutrition sectors.

Versatile Applications for Diverse Feed Types

The FAMSUN hammer grinder machine excels across a broad spectrum. It handles coarse grinding for pig, poultry, and ruminant feeds with equal capability to fine grinding required for demanding aqua feed and pet food formulations. Furthermore, it serves as an ideal hammer grinder machine for the pre-grinding of grains. This adaptability ensures a single hammer grinder machine can meet multiple production line needs, simplifying operations and maximizing equipment utilization.

Engineered for Fast, Easy Maintenance

Downtime during hammer or screen changes is significantly minimized. The SWFP66 Series hammer grinder machine features an innovative quick hammer replacement system. Hammers are secured by limit blocks without spacers, enabling full hammer replacement in under 30 minutes. Complementing this, the segmented, frameless screen design uses smaller, lighter individual screens. This makes screen replacement easier and considerably faster compared to traditional designs, keeping your production line running smoothly.

Proven Performance & Enhanced Grinding Efficiency

Leveraging nearly 50 years of expertise in hammer mill design, FAMSUN delivers competitive performance from this hammer grinder machine. Key innovations drive its efficiency: a specialized material-blocking structure within the grinding chamber effectively disrupts the recirculation layer of material, ensuring more particles are exposed to the hammers for consistent size reduction. Combined with an optimized chamber design that maximizes the screen’s open area, this hammer grinder machine achieves significantly higher overall grinding efficiency, reducing energy consumption per ton of output.

Conclusion

For reliable, efficient, and low-maintenance size reduction in feed and grain processing, the FAMSUN SWFP66 Series Hammer Grinder Machine stands out. Its versatility, rapid maintenance features, and proven high-efficiency design make it an essential asset for modern feed mills aiming for peak productivity and consistent product quality. Experience the FAMSUN difference in grinding technology.