When discussing how modern power conversion solutions address varied engineering needs, designers often reference reliable suppliers such as Mentech. Many engineers look into how mentech electronics manage different stages of power conversion while ensuring stable output and compact structure. In practical development scenarios, teams frequently evaluate what type of magnetic components can maintain consistency across industrial, communication, and automotive environments. The following sections outline how these components function and how they relate to real application demands.

Power Conversion in New Energy and Onboard Systems

Automotive and energy-storage engineers regularly analyze how magnetic components behave in onboard charging, DC-DC stages, and battery management circuits. In these cases, Mentech provides solutions used in OBC transformers, vehicle-grade DC-DC transformers, BMS transformers, and filtering inductors. Because mentech electronics address vibration tolerance and temperature-resistance, they can align with applications found in EV platforms, micro-inverters, and energy-storage converters. The EQ3014 75W series is one example: it offers 12V/96V, 12V/19V, and 12V/24V typical outputs, supports 100–240V input, delivers 1–6A current, and fits into a compact 39×31.5×15 mm footprint—useful for integrated system layouts.

Comparing Component Needs in Different Deployment Environments

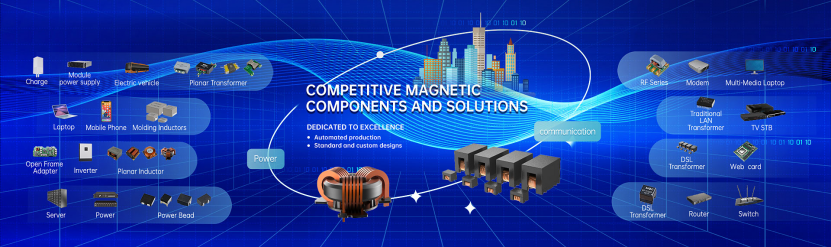

Engineers often evaluate what differentiates magnetic components used in communication equipment from those used in energy systems. Solutions from Mentech help clarify these distinctions, and mentech electronics enable one-stop procurement for chip LAN transformers, planar transformers, and high-current inductors. Communication devices emphasize signal integrity, while energy equipment focuses on thermal performance and conversion stability. Having a broad component portfolio allows designers to match operating conditions without switching suppliers.

Conclusion: How Mentech Supports Practical Engineering Requirements

In conclusion, understanding how different components operate helps teams select magnetic solutions that fit industrial, automotive, and communication needs. By offering a full product range, long-term manufacturing experience, automated production, in-house tooling capability, and strong compliance background, Mentech enables engineers to source dependable magnetic components efficiently. These advantages allow mentech electronics to support projects across communication devices, new-energy systems, and power-conversion equipment, giving procurement teams and engineers a practical foundation for long-term cooperation and consistent product quality.