Edge banding is a critical process in modern woodworking, where precision and quality are paramount. The edge banding machine is designed to apply a decorative and protective strip along the edges of panels, enhancing both the aesthetic and durability of the product. A well-designed automatic edge banding machine can make this process more efficient and consistent. HUAHUA CNC provides high-performance machinery that improves the edge banding process for manufacturers, offering advanced technology and features that optimize productivity.

How an Automatic Edge Banding Machine Enhances Precision

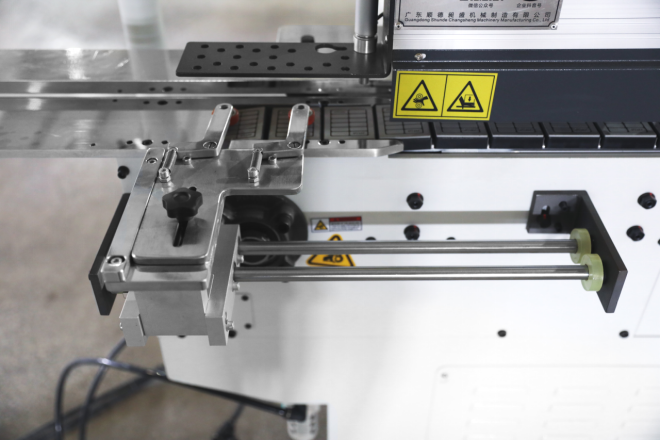

In any production setting, precision is key. HUAHUA CNC’s automatic edge banding machine helps achieve this by ensuring uniform application of the edge banding material. The machine’s high-tech design includes features like an advanced color control screen and precision-guided rollers that ensure each panel receives a smooth, flawless edge. This allows manufacturers to maintain a high level of accuracy even during high-speed operations, making it ideal for large-scale production runs.

Why Edge Banding Machines Are Essential for Different Panel Types

Different types of panels require different treatments, and the edge banding machine is versatile enough to handle a wide range of materials and thicknesses. Whether it’s a narrow panel edge or a thicker one, HUAHUA CNC’s automatic edge banding machine is designed to accommodate variations in panel sizes, making it ideal for custom jobs. With a minimum panel thickness of 10mm and the ability to work with edge tapes up to 63mm wide, this machine is versatile and ready for multiple production scenarios.

Technological Advancements in Automatic Edge Banding Machines

The latest automatic edge banding machines come with a host of new technologies aimed at improving efficiency. HUAHUA CNC has integrated features such as a double glue pot, allowing for different glue colors based on the edge tape and panel color, which resolves the issue of visible glue lines. Additionally, the machine’s trimming and scraping mechanisms ensure a cleaner, more polished finish, improving the overall quality of the product.

Conclusion

The automatic edge banding machine has revolutionized the woodworking industry by ensuring that edge banding is applied quickly, consistently, and with a high degree of precision. HUAHUA CNC continues to innovate with these machines, offering advanced features that meet the growing demands of modern manufacturing. By incorporating automation into edge banding, businesses can expect higher production rates, better quality, and a reduction in manual labor.